MERIT

MinebeaMitsumi’s integrated mold sensing system

Merits of introducing the system

MERIT

O1

Ensuring uniform molding quality among cavities

- Problem

Even though molds are made according to drawings, there are differences among cavities due to various factors, resulting in variations in quality of molded products.

- Effect of introducing the system

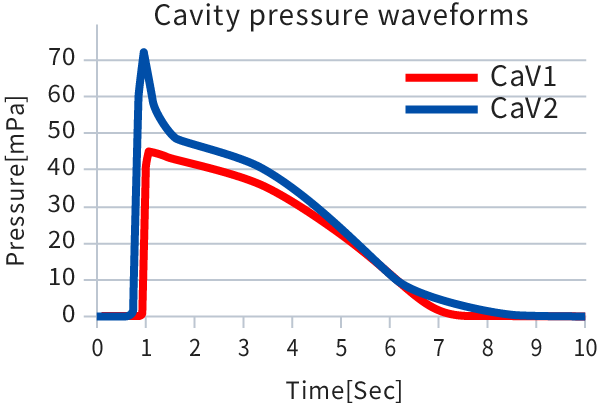

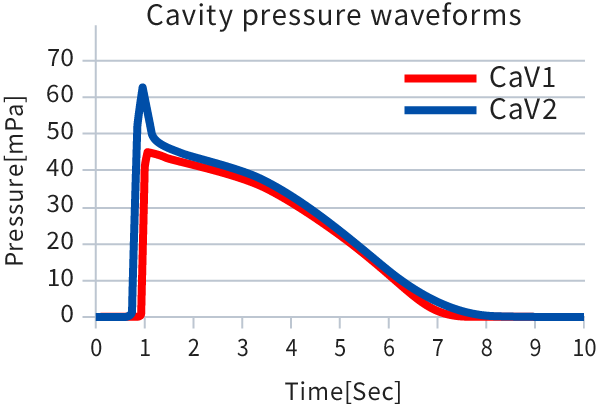

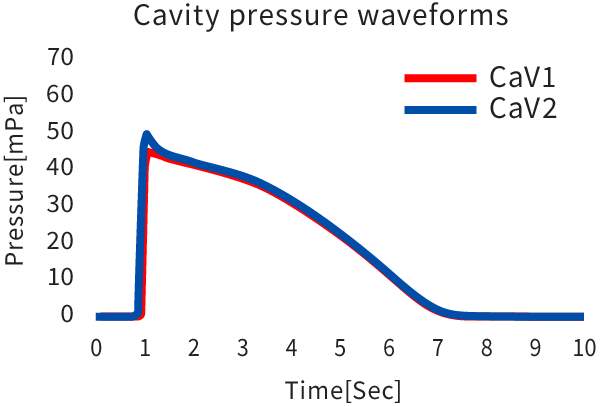

By bringing cavity pressure waveforms closer to each other, it becomes possible to reduce the differences among cavities in terms of the weight/dimension of molded products and thereby ensure that products have stable, uniform quality

Adjusting the mold so that Cav1 and Cav2 waveforms come closer to each other

Minimized differences ensure uniform quality!

| Cav1 | Cav2 | Difference | |

|---|---|---|---|

| Weight [g] |

24.990 | 25.021 | 0.031 |

| Dimension [㎜] |

22.745 | 22.956 | 0.211 |

| Cav1 | Cav2 | Difference | |

|---|---|---|---|

| Weight [g] |

25.024 | 25.029 | 0.005 |

| Dimension [㎜] |

22.916 | 22.961 | 0.045 |

| Cav1 | Cav2 | Difference | |

|---|---|---|---|

| Weight [g] |

25.028 | 25.026 | -0.002 |

| Dimension [㎜] |

22.949 | 22.959 | 0.010 |

Bringing the waveforms closer to each other leads to reduced differences in weight and dimension

Minimized differences ensure uniform quality!

MERIT

O2

Reproducing molding conditions

- Problem

A mass production factory cannot make normal products using molds that were transferred to it if the molding conditions were set in a prototyping factory

- Effect of introducing the system

The mass production factory can set molding conditions smoothly by adjusting the conditions based on the reference cavity pressure waveform obtained in the prototyping factory

-

The domestic prototyping factory sets the conditions

-

Cavity pressure waveform data obtained when the conditions were set is delivered as a csv file or the like

-

The overseas mass production factory can smoothly produce normal products by adjusting the molding conditions based on the cavity pressure waveform data

MERIT

O3

Improving production efficiency

- Problem

Workers relied on intuition and experience to determine and specify the dwelling time and the number of trial shots for molded products

- Effect of introducing the system

After determining the best timing based on cavity pressure and temperature waveforms, it became possible to specify that timing to improve the production efficiency

-

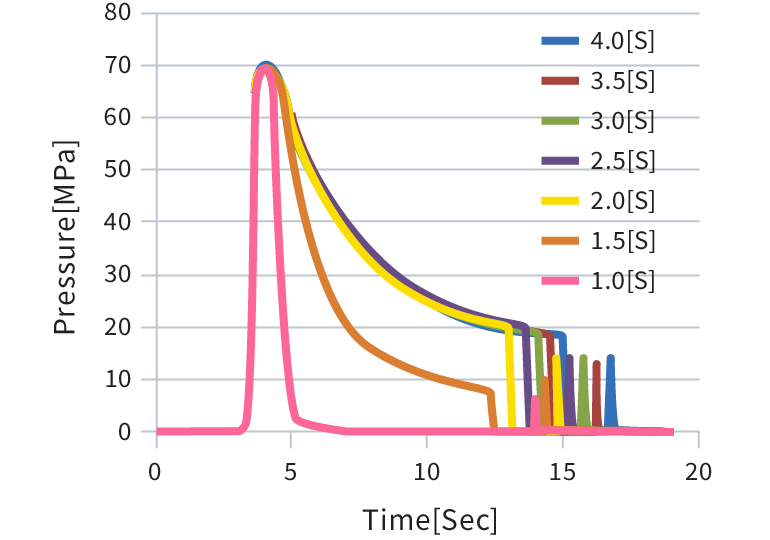

Determining the gate seal time

- Waveforms of cavity pressure with

different dwelling times

The dwelling time was changed from 4.0 seconds in units of 0.5 seconds. From the fact that the cavity pressure waveform for a dwelling time of 1.5 seconds shows a sudden pressure drop, 2.0 seconds is set as the gate seal time. The dwelling time can be reduced to the minimum necessary length based on the data.

- Waveforms of cavity pressure with

-

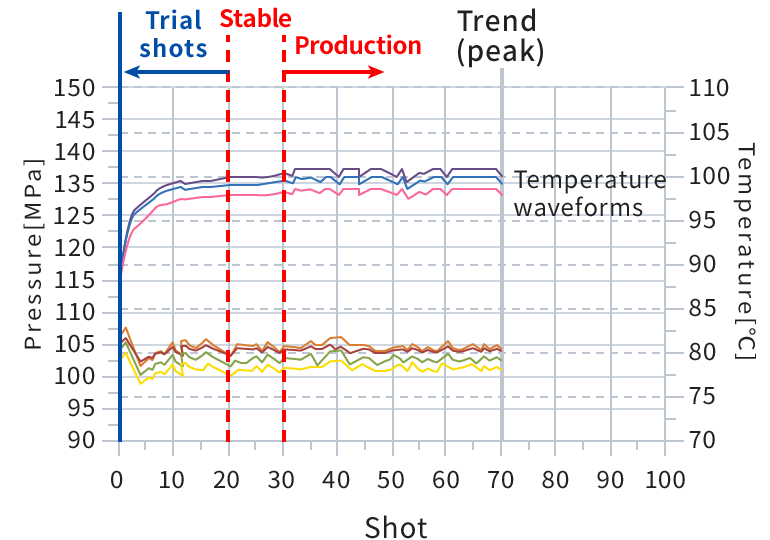

Determining the number of trial shots

- Waveforms of mold temperature from

the start of molding

The mold temperature became stable when 20 to 30 shots of resin were injected after the start of molding. The number of trial shots can be determined based on the data.

- Waveforms of mold temperature from

MERIT

O4

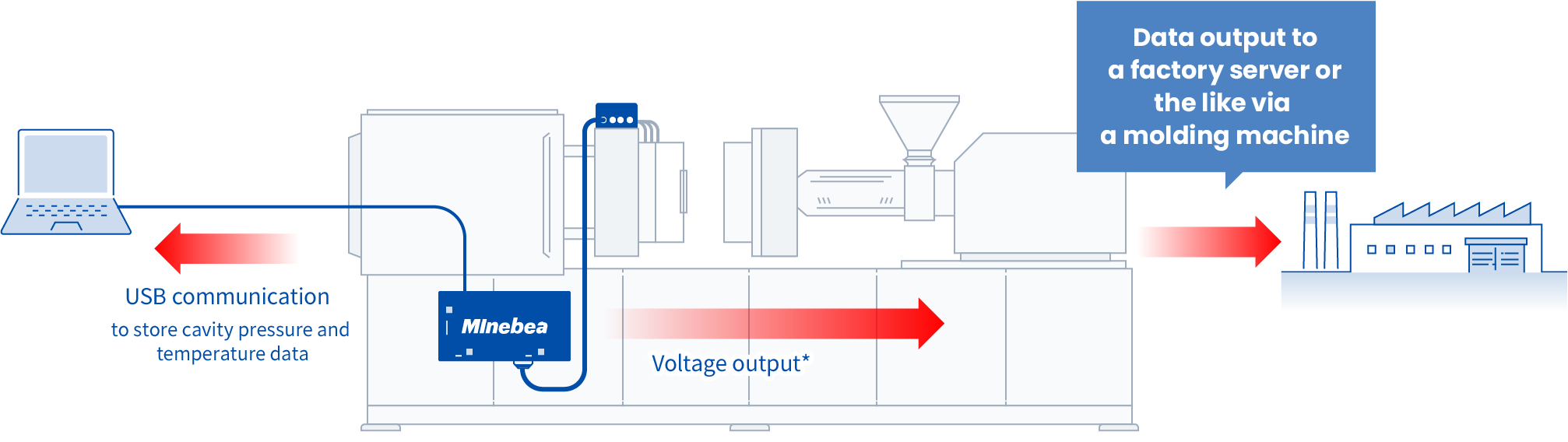

Acquiring traceability logs

- Problem

There are no quantitative quality records of molded products on a shot-by-shot basis

- Effect of introducing the system

By using the cavity pressure and temperature data output from the system, it becomes possible to keep and manage cavity pressure waveforms of all mass-produced products as quantitative quality records

* To connect the voltage output to an injection molding machine, it is necessary to consult its manufacturer about the specifications.

MERIT

O5

Reducing inspection costs

- Problem

100% visual inspection was required to detect unpredictable short shots

- Effect of introducing the system

It became possible to detect short shots from cavity pressure waveforms and sort out defective products accordingly. Consequently, 100% inspection was changed to sampling inspection, leading to a reduction in inspection costs.

Case of company A

-

Before

introducing

the system- 100% inspection

-

168

inspectors needed

-

After

introducing

the system- Sampling inspection

-

Reduced to

81

inspectorsCost reduced by about8.5million yen a year